WHAT WE'LL DO

THE IMPLEMENTATION OF OPTIMOULD32 SOFTWARE THROUGH ARM SYNCHRONISATION OF FACTORY SCHEDULING

ARM SYNCHRONISATION IS THE OPTIMISATION OF:

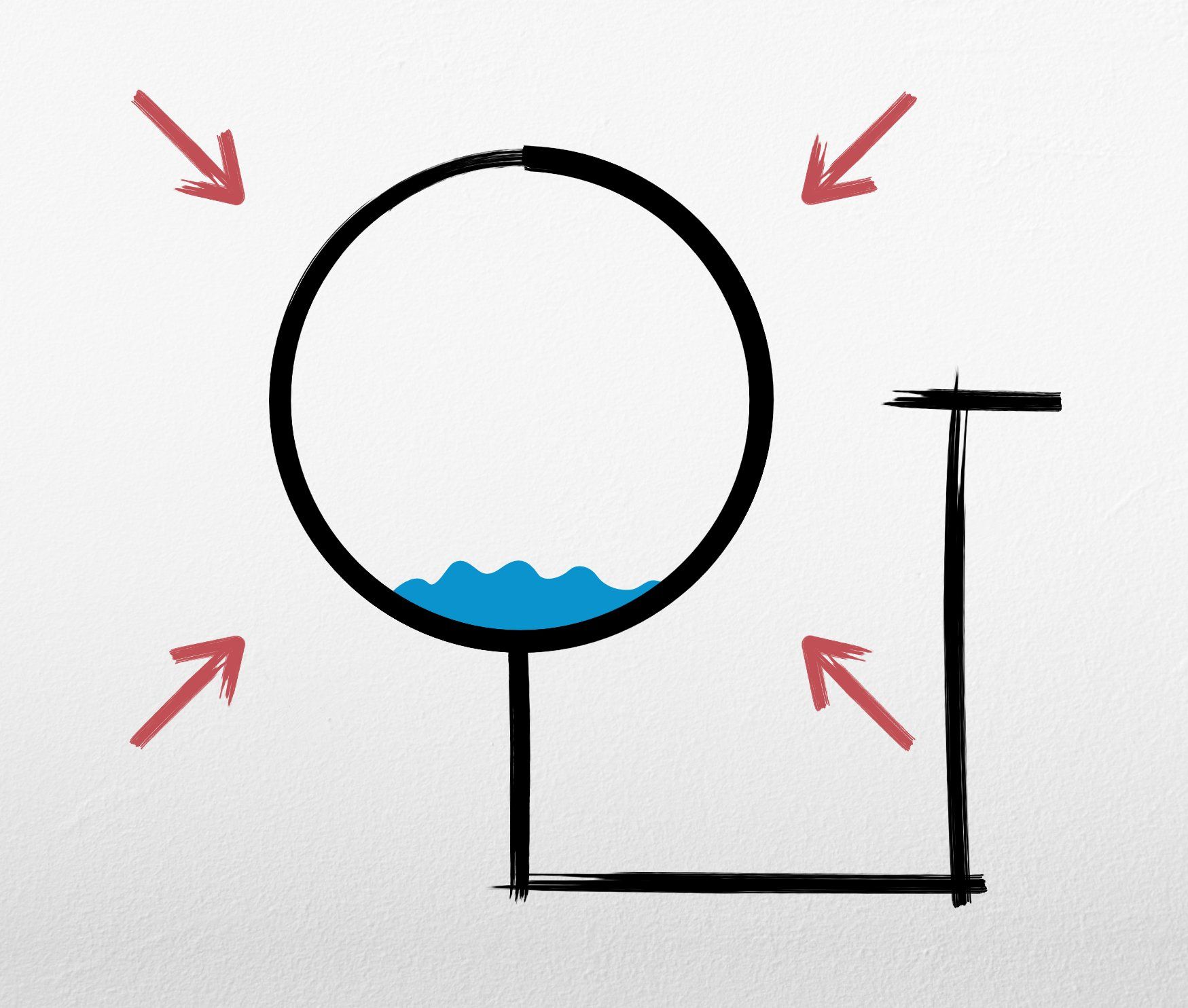

• Arm order by machine - recipe instruction

• Cooling station - including hardware modifications

• Arm timing - uninterrupted arm travel (full travel cycle)

FACTORY SCHEDULING IS THE OPTIMISATION OF:

• Machine synchronisation for floor operator/supervisor utilisation optimisation

01

| Current Operating Time (mins) | Operating Time with Arm Sync (mins) | % Change | |

|---|---|---|---|

| Cycle Time | 111 | 79 | -20% |

| Oven Empty | 42 | 10 | -76% |

| Production Rate | 24 CPS | 36 CPS | +50% |

02

| Current Operating Time (mins) | Operating Time with Arm Sync (mins) | % Change | |

|---|---|---|---|

| Cycle Time | 119 | 80 | -33% |

| Oven Empty | 42 | 3 | -93% |

| Production Rate | 24 CPS | 36 CPS | +50% |

BOTH EXAMPLES ARE BASED ON ACTUAL MACHINE RECIPES AND TIMINGS.

Data collected from production machine history used solely for productivity documentation for Optimould.